Assembly Show South ♦ May 1-2 ♦ Booth #929 More Information

Orbitize Your Inbox

-

Core Processes

- Core Processes

- Impact Riveting

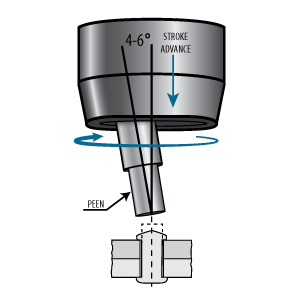

- Orbital & Radial Forming

- Roller Forming

- Hot Upset Forming

- Specialty Press

- Process Intelligence

- All Processes and Services

- All Standard Products

-

Automation & Testing

- Automation

- Conveyors

- Solutions Lab

- Testing Equipment

- All Processes and Services

- Equipment Support

- Blog

- Downloads

- Contact an Expert

We use cookies to ensure that we give you the best experience on our website. By continuing to use our site, you accept our cookie policy.

Accept